ҮЙЛЧИЛГЭЭ

Дело клиента

2016year1month1day In this paper a cone crusher is modelled and simulated using DEM in the commercial software EDEM® provided by DEM-Solutions Ltd. Cone crushers and

узнать больше

2021year3month15day 1. Introduction As one of the key equipment in the bulk materials crushing system, the cone crusher is mainly used for the

узнать больше

2016year1month1day In this paper a cone crusher is modelled and simulated using DEM in the commercial software EDEM® provided by DEM-Solutions Ltd. Cone crushers and

узнать больше

2009year10month1day Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during one eccentric rotation of the cone was

узнать больше

2009year10month1day Solving practical problems in cone crusher design, the quantity of rock material falling out of the crushing chamber during one eccentric rotation of the cone was

узнать больше

2019year3month21day The crusher will be most effective when the mobile cone rotates around its axis. In that case, force Fro acts on the piece, creating an internal torque. Such behavior

узнать больше

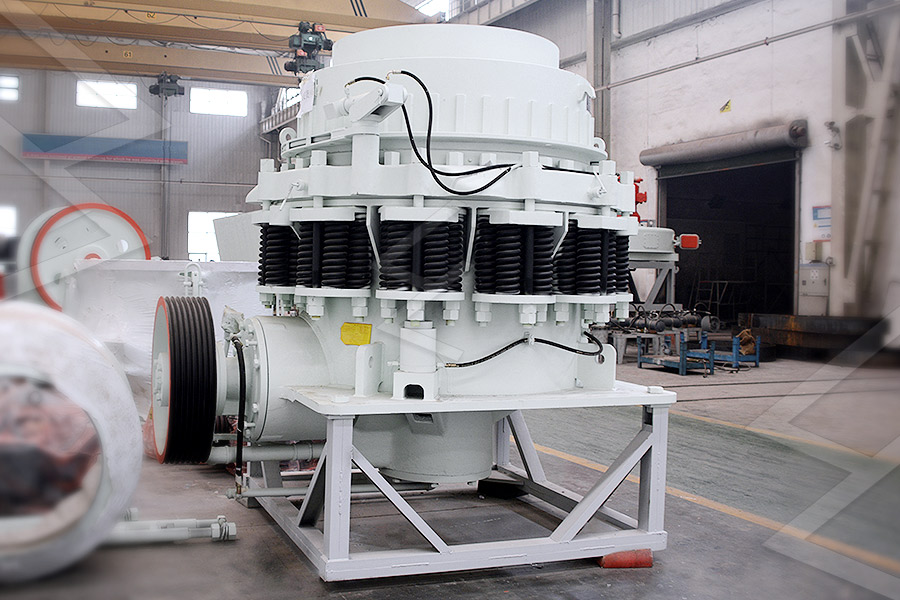

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a

узнать больше

2021year2month4day Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher.

узнать больше

2015year5month13day Cone crushers are used by both the aggregate producing and the mining industry. Both industries are interested in increasing the product quality while at the same time lowering the production...

узнать больше

Below are suggested speed guidelines for CMB Cone Crushers: Low speed: Secondary applications, after a Jaw Crusher. Medium speed: Gravel applications with coarse feed. Standard speed: Tertiary applications (0 x 1/2”) High speed: Sand applications (4m or less) Speed ranges: Smaller head diameters (48” or smaller): 750-1,200 rpm.

узнать больше

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site . Read More Cone Rock Crusher Обработка. Cone Rock Crusher Обработка; Rock Crusher Cones vanderhamtechnieknl.

узнать больше

An improved cone-style rock crusher. The rock crusher may be adjusted for varying rock crushing specifications, including different speeds, throws, and liners. The rock crusher comprises a frame that supports a crushing bowl, a crusher head and a shaft, with the shaft being secured to the crusher head. A domed feed plate may be secured onto the ...

узнать больше

However, when correctly used, a cone crusher offers lower operating costs than a conventional impact crusher. Therefore, clients crushing hard or abrasive materials are advised to install cone crushers for the final crushing and cubicising stage. ... This means that cone head must be covered by rock. Stable and continuous feed. Material below ...

узнать больше

2021year8month11day Fig. 1 presents a simplified diagram of a cone crusher. Cone crushers consist of a circular outer concave enclosing a cone-shaped mantle that moves eccentrically, see Fig. 1. As the distance between the mantle and concave inner wall increases, rock particles fall; when the distance de-creases, the particles are compressed and crushed.

узнать больше

Nordberg® HP Series™ cone crushers. Nordberg® HP Series™ is the most popular cone crusher family in the world with over 10,000 machines sold globally. Nordberg® HP Series™ cone crushers are well performing and reliable rock crushing machines for all aggregates production, quarrying and mining applications.

узнать больше

Cone crushers have gained such wide acceptance that they may be regarded as standard in the intermediate-range size-reducing machines. A schematic diagram of a cone crusher is shown in Fig. 4.6 A.The drive is similar to that of a gyratory crusher. The inner cone or ‘crushing head’ is supported by the tapered concentric spindle, which is rotated by the

узнать больше

2017year1month5day rock will overload the crusher and can cause the bowl or cone to float. “With float, the crusher will lose the closed-side setting (CSS) and more oversize rock will pass through and increase the amount of recirculating material,” he says. “Such events can also increase fatigue and can damage the crusher or cause a catastrophic failure.”

узнать больше

2020year6month3day Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries. Inside the crusher, a piece of steel, known as the mantle, rotates eccentrically.

узнать больше

2023year11month9day Superior’s Patriot Cone Crusher is an American-made, bushing-style rock crusher that sets the standard for productivity and durability. With a lifetime warranty and high-grade components that exceed industry standards, the Patriot Cone delivers reliable performance and unbeatable value in secondary or tertiary applications.

узнать больше

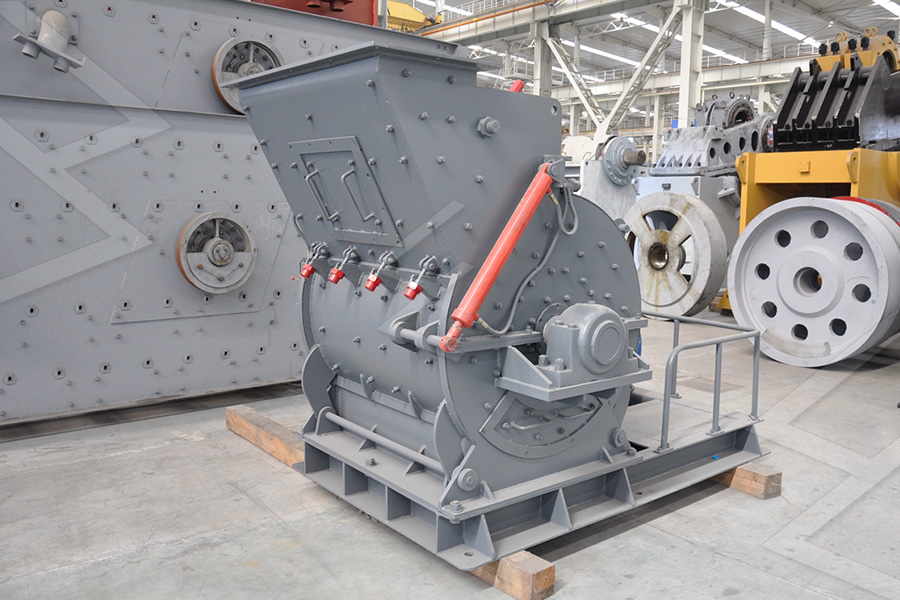

2023year5month12day The six best-selling granite crusher machines are jaw crusher, cone crusher, impact crusher, sand making machine, mobile crusher, and portable crusher. This article will share with you the pros and cons of these granite crusher machines to help you pick the right one. The reason for the popularity of granite rock crushing equipment is the

узнать больше

Nordberg® HP500™ cone crusher is a versatile rock crushing machine often used in aggregates production, quarrying applications and mining operations on secondary, tertiary or quaternary crushing stage. It is designed for high productivity, low operating and wear costs, long service life and high efficiency, providing high quality product.

узнать больше

Contribute to businessgitv/ru development by creating an account on GitHub.

узнать больше

2017year3month4day A cone crusher breaks rock by squeezing the rock betwe en an eccentrically gyrating spindle, which is cov ered by a wear resistant mantle, and the enclosing concave hopper, covered by a mang anese ...

узнать больше

2015year5month13day crusher may alternatively be an impact crusher if the rock is particularly difficult to shape. 1.2 C RUSHING OF M INERAL O RES In the mining industry crushing is the first mechanical stage in the ...

узнать больше

Cone and thread tubing is 1/8-hard 316 seamless stainless steel tubing that has an undersized outside diameter to assist in coning and threading operations when the tube is used with cone and thread fittings. swagelok.cn. swagelok.cn. 锥形和螺纹卡 套管是 1/8 硬度 316 不锈 钢无缝卡套管,这些卡套管采用略小的 ...

узнать больше

2016year1month1day The same approach for rock particle modelling was further on applied to a H6000 cone crusher (Quist, 2012). Other attempts on modelling the cone crusher have recently by presented by Li et al., 2014, Delaney et al., 2015 and Cleary and Sinnott (2015). There are mainly three different approaches for modelling the rock material breakage in

узнать больше

2021year2month4day Inertia cone crushers are widely used in complex ore mineral processing. The two mass variables (fixed cone mass and moving cone mass) affect the dynamic performance of the inertia cone crusher. Particularly the operative crushing force of the moving cone and the amplitude of the fixed cone are affected, and thus the energy

узнать больше

An improved cone-style rock crusher. The rock crusher may be adjusted for varying rock crushing specifications, including different speeds, throws, and liners. The rock crusher comprises a frame that supports a crushing bowl, a crusher head and a shaft, with the shaft being secured to the crusher head. A domed feed plate may be secured onto the crusher

узнать больше

2018year12month18day The HP cone crusher is a com-pressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger rock particles are crushed directly between the surfaces of the mantle and bowl liner. This is called single layer crushing. Smaller rock particles are crushed between other rock particles, which is

узнать большеузнать больше